Keberlanjutan

Keberlanjutan

Sustainability Roadmap : Vision 2030

Sustainability has always been at the core of our business. At the Company, we strive to create products and deliver services in an environmentally conscious manner through responsible and sustainable innovation at every stage of the product’s life.

In our Sustainability Roadmap: Vision (SRV) 2030, we broken down our approach into three pillars—Production, Forest, and People, which in line with UN Sustainable Development Goals (SDG). We have set ourselves targets for each of these pillars, intending to drive improvement in processes that concern our business, wider supply chain and environmental sustainability.

The company took concrete steps towards improving our ESG performance by collaborating with external partners to create a plan for decarbonization roadmap and evaluate our ESG performance.

|

Production |

Forest |

Man |

Pillar 1 – Production : Carbon Footprint Reduction

We keep continually innovate whole production process to guarantee our products have a longer lifetime and able to minimize arising waste.

Pillar 2 – Forest : Conserving the Forest

The Company as part of APP is supporting the effortsin achieving landscape-scale sustainable forest management, protection and restoration across APP and its supplier concessions.

Pillar 3 – People : Improving Lives

We seek to empower and involve communities in our operations through their input, thereby facilitating their growth and maximizing sustainability and collective growth.

Sustainability Policy

In effort to increase performance facing global competition and challenges, which aligned with Sustainable Development Goals (SDG), the Company develops and enhances Quality (ISO 9001:2015), Environment (ISO 14001:2015), Occupational Safety and Health (SMK3 & ISO 45001:2018), Energy (ISO 50001:2018), Procurement Fiber and Social and Security Management System based on Vision , Mission , Strategic Planning which aligned with APP policy .

|

ISO 9001:2015 |

ISO 14001:2015 |

ISO 50001:2018 |

ISO 45001:2018 |

We implemented by maximizing resources and using clean & efficient energy to implement green industry and achieve satisfaction of all parties involved both internally and externally (link). In generally, the Company’s sustainability policy covering as follows :

- Implements responsible management to all its fiber suppliers as a priority of its commitment to sustainable operation and environmental protection. The fiber used to manufacture our pulp and paper products are either source from 100% plantation wood, sustainably managed forests, or recycled fiber from imported and local sources. (link)

- Address land and forest fires in area where we operate based on global best practices for fire management. We commit to prevent and manage land and forest fires. (link)

- Implement Sustainable Forest Management (SFM), including the protection and conservation of High Conservation Values (HCV) and High Carbon Stock (HCS), including biodiversity. (link)

- Maintain and implement Food Safety Management System and Halal Assurance System consistently within the supply chain of the product from material purchase, production process, storage and product distribution to provide assurance of Safety & Halal paper product to customer. (link)

- Achieving better environmental performance and developing environmentally friendly products to maintain sustainability in our business. We are committed to responsibly manage the available resources and minimizing environmental impacts from all our operations. (link)

- Conducting the business in a manner that ensures the health and safety of its workers, visitors, and complies with relevant legislation, codes of practice and other requirements. We ensure that appropriate arrangements are in place to comply with all duties and enable the pursuit of continuous improvement in its operations and management systems. (link)

- Recognizes the responsibility to respect human rights throughout our operations and commit to respecting the rights of our worker and the communities surrounding our operations and our other stakeholders. (link)

- Ensure the operation operate ethically, taking into consideration aspects of human rights, social and economics, as well as environmental. ( link )

Sustainability Structure

As multinational companies and as part of Sinarmas Asia Pulp & Paper (APP), the Company believes that for long-term success, we need create values for stakeholder interests. We integrate the values and break down effort and strategy towards to UN SDGs and the Paris Agreement on climate change.

As a company that relies on natural resources, Tjiwi Kimia commit to manage and handle risks and opportunities of Environmental, Social and Governance (ESG) related to the operations. The Company recognizes that sustainability, ESG and financial performance have become inextricably linked. Tjiwi Kimia believes that ESG is a critical aspect of all business that should be focused on given the impact on long-term business continuity, including water & energy efficiency, waste management, carbon emission reduction, biodiversity, environment management system, product certification, OHS management, security management, social compliance, social responsibility, code of conduct, transparency and stakeholder engagement.

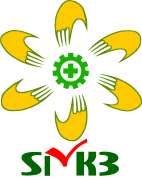

Our commitment for Sustainability proven in whole aspects of our operations in manage natural resources, integrated from upstream to downstream and 3R implementation. Furthermore, Tjiwi Kimia builds supporting plant for main operations as follows power plant, fresh water treatment plant (FWTP), waste water treatment plant (WWTP), waste temporary storage, and multiblock plant, so all resources can be well managed in accordance to applicable regulations and standards.

Sustainability SideNav

Sustainability Overview

- QUALITY MANAGEMENT & PRODUCT CERTIFICATION

- ENVIRONMENT AND CHAIN OF CUSTODY MANAGEMENT

- WATER CONSUMPTION EFFICIENCY

- WASTE WATER TREATMENT

- ENERGY CONSUMPTION EFFICIENCY

- EMISSION REDUCTION

- SOLID WASTE MANAGEMENT

- BIODIVERSITY

- OHS MANAGEMENT

- SECURITY MANAGEMENT

- SOCIAL COMPLIANCE

- BUSINESS CODE OF CONDUCT

- CORPORATE SOCIAL RESPONSIBILITY

- TRANSPARENCY & STAKEHOLDER ENGAGEMENT

QUALITY MANAGEMENT & PRODUCT CERTIFICATION

The Company is fully committed to produce high quality paper products. Its products are marketed in both national and international markets. The mills’ products comply with quality standard, environment, safety and health product regulations including standards set by USA, European, Japan, and other Asian markets. In commitment, the Company has implementing and certified ISO 9001:2015 Quality Management System.

To increase the competitiveness of the national industry, the government encourages industrial companies to apply green industry principles by prioritizing efforts to efficiently and effectively use resources sustainably in the production process to be able to align industrial development with the preservation of environmental functions and to provide benefits to society. The company has succeed reaching certification in various schemes, like Indonesian Eco-label certificate since in 2006, continued in 2009 Green Seal™ certificate from the United States, and Singapore Green Label certificate since in 2019. In 2022, the company received the Green Industry Standard certificate from the Ministry of Industry of the Republic of Indonesia.

|

Ecolabel Indonesia

|

Singapore Green Label |

Green Seal

|

Standar Industri Hijau

|

Another advantage in aspect quality which is also achieved by the Company, as following :

- ISO 9706 since 2004, stated that the Company's products have superiority in endurance For saved as archive.

- Food packaging paper products have passed laboratory tests accordance with international regulations since 2005 including SNI (Indonesia), FDA (United States), RoHS (Europe), BfR (Germany), and GB (China). It means that the food wrapping paper products produced by the Company are safe from harmful metals and chemical substances, and no transferring cause of paper material to the food.

- Paper products produced by the Company have also obtained halal certificates from the Indonesian Ulema Council (MUI) since 2012, which were subsequently renewed with halal certificates issued from the Halal Product Assurance Agency - Ministry of Religion of the Republic of Indonesia from the end of 2022 until now. The Company’s paper and chemical products have also been SNI certified and the TKDN value verified by the Ministry of Industry of the Republic of Indonesia.

|

|

|

ENVIRONMENT AND CHAIN OF CUSTODY MANAGEMENT

In the production process activities, the Company uses various natural resources, including pulp, fuel, chemicals and water. To ensure the sustainability of our operations, we commit to manage resources optimally and responsibly, by identifying and reducing negative environmental impacts. The Company always implements applicable regulations and standards, as well as a circular economy, in the environmental management. The implementation has been certified ISO 14001:2015 (Environmental Management System) and ISO 50001:2018 (Energy Management System). The Company has participated in the corporate performance appraisal program in environmental management (PROPER) from the Ministry of Environment and Forestry and the company received a Blue rating (Comply).

The application of a circular economy in the Company includes the use of raw materials and waste management in a responsible manner. The use of raw materials in the form of waste paper that can be recycled with a composition of 40% of the total raw materials to produce white and brown paper. The Company also ensure the pulp as a main raw material have been certified by PEFC and SVLK scheme. This is in line with the implementation of the Forest Conservation Policy, and the Fiber Procurement and Processing Policy. The company ensure that the fiber origin not come High Conservation Value (HCV) area and does not originate from illegal logging. The raw material procurement process has also been verified through Ecolabel certification and Due Diligence system to supplier to ensure pulpwood traceability, environment management, and compliance to related regulation, which been done periodically once a year.

WATER CONSUMPTION EFFICIENCY

Contributes to UN SDG :

To support operations, the Company uses water for the following purposes: steam generation, heating, cooling and cleaning. Therefore, the Company has continued efforts to save water by re-using and recycling the remaining process water. The Company recognize that water scarcity and water stress is a serious climate risk, and we adopt Board-level responsibility in managing this problem. The Company’s mill is located nearby body of water, making it easier to access raw water. On the other hand, water scarcity can also impact operations, which may occur during the dry season. Therefore, the Company continues to monitor raw water discharge and quality strictly and conducts periodic testing.

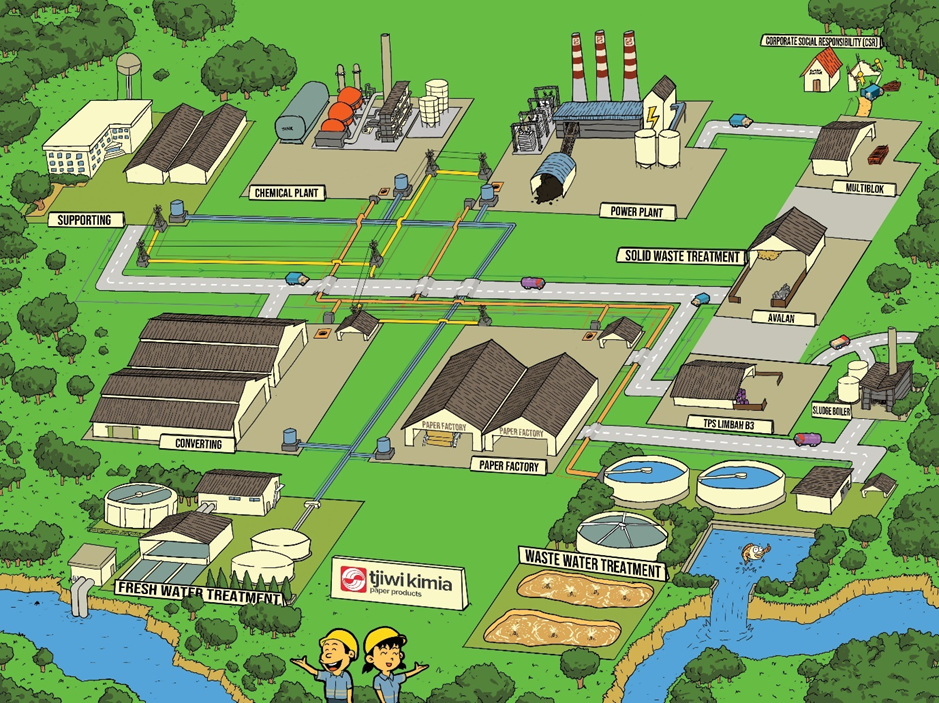

The Company is located near with the river and can make direct access to consume the raw water. We process the raw water from river before it used for production and other operational, as following :

In general, raw water treatment includes water intake, sedimentation, flocculation and coagulation processes (water purification), water filtration process (filtration) using filter media, the process of disinfection to kill germs / micro-organisms, then the fresh water collected in reservoir before it distributed.

To ensure the sustainability of our business, and considering these risks, we have undertaken programmed to specifically reduce our freshwater use. In 2022, our water consumption reduced by 9% compared to 2021. Several innovations were made to reduce water consumption, including improve production efficiency, stop the pipeline leakage and other equipment, reuse/recycle water from process residue.

WASTE WATER TREATMENT

Contributes to UN SDG :

The company does management waste liquid refer to Agreement Appropriateness Environment Live by the Governor East Java . Monitoring and evaluation from results activity management environment life reported every 6 months very to agency Government related .

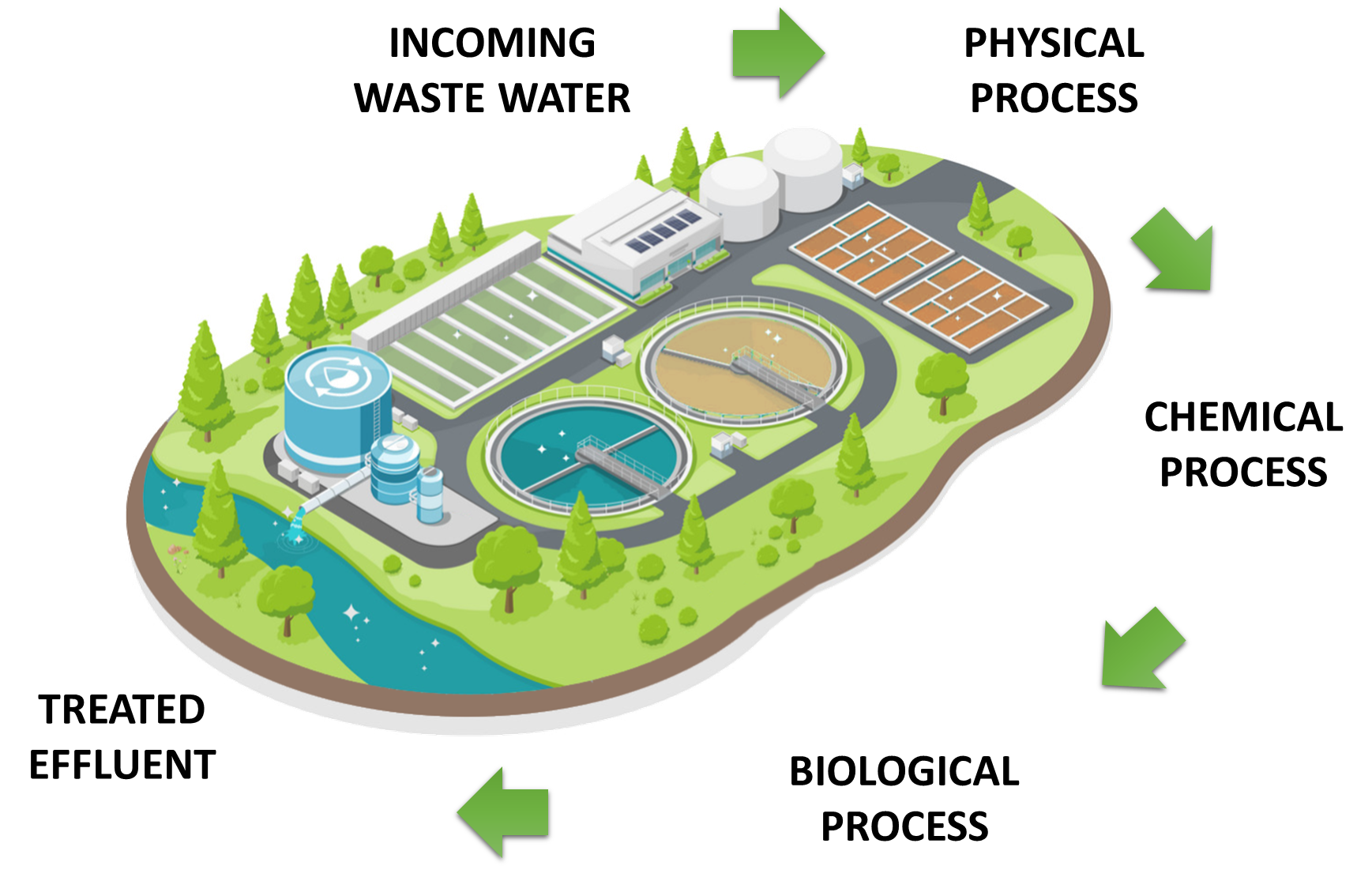

The company get Waste Water Discharge Permit, in condition waste water must be proceed in Waste Water Treatment (WWTP) and fulfill the standard regulation, before it discharged back to the river. Waste water treatment aims to reduce concentration and load parameter through 3 process stages: physical, chemical and biological processes, as following :

- Physical Process: homogenization and separation process solids from waste water.

- Chemical Process: binding process solids from waste waster by coagulation and flocculation.

- Biological Process: treatment for substance organic in wastewater (COD) to fulfill standard regulation

After the treatments, the Company periodically check effluent water quality before discharged back to the river, in accordance to government regulation.

The Company commits to minimizing waste and maximizing opportunities to reuse waste materials through the ‘3R’ strategy—reduce, reuse and recycle which helps us to maximize the value of resources at every stage of the life cycle, as stated in the Company’s policies.

- In 2022, the Company reduce fiber loss from waste water remaining from the paper production process by 12% compared to 2021.

- Application of 3R to sludge waste from the wastewater treatment process at WWTP, by reusing 100% sludge as a substitute raw material for brown paper production and as a substitute fuel (non-fossil) in steam production in sludge boilers.

Until this moment, the company did not incur any fines or penalties for violations of environmental regulations. There were no industrial accidents or spills.

ENERGY CONSUMPTION EFFICIENCY

Contributes to UN SDG :

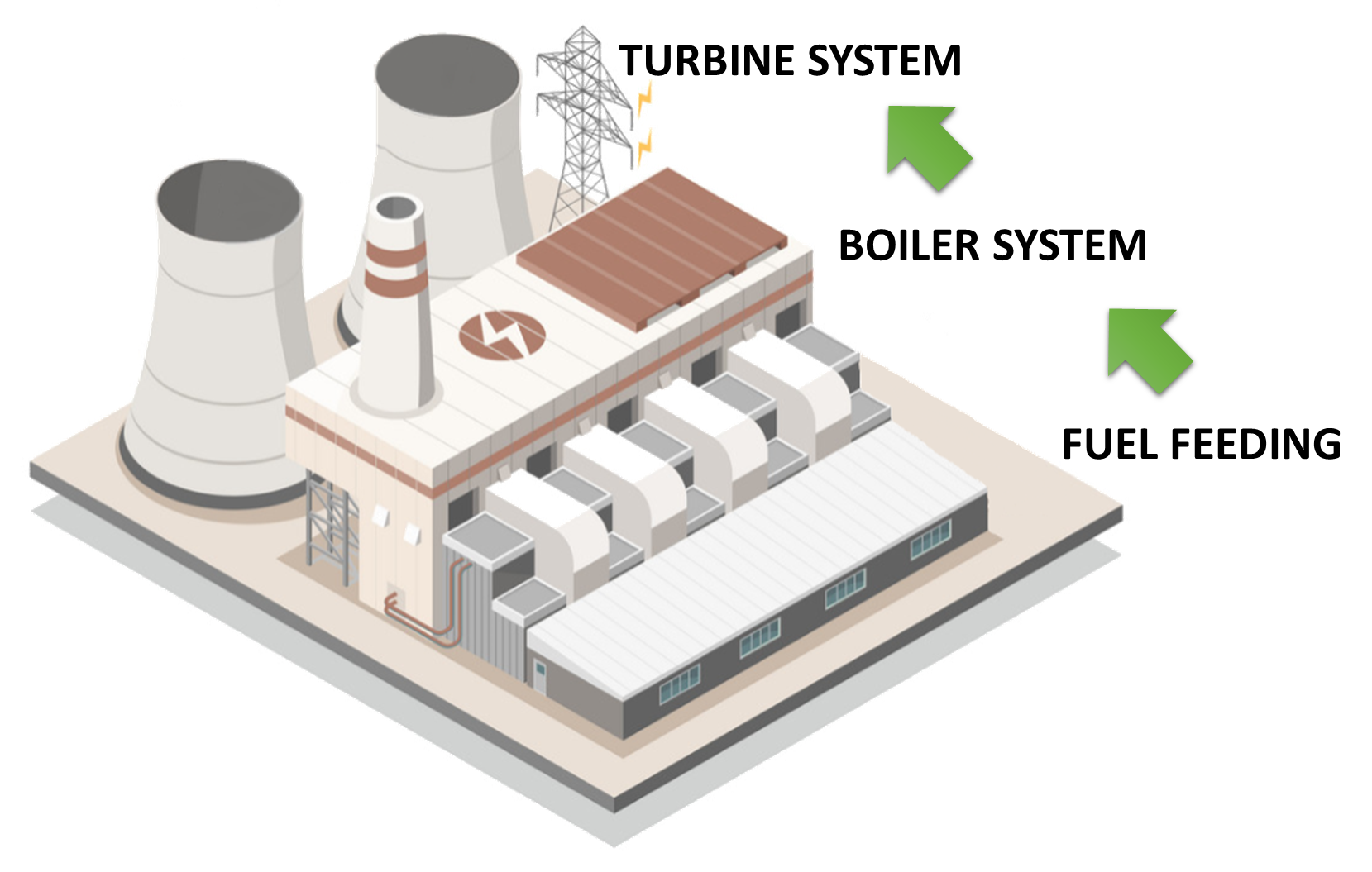

To fulfill electricity and steam needs especially in the production process, despite getting supply electricity from PLN, the Company also has its own co-generator. In general, the boiler generates high pressured steam to drive the turbines to produce power. Moreove r, high pressured seam is also converted and distributed to the production process paper as low pressured steam for the paper drying process.

Energy conservation is an important consideration and main concern for us, through energy reduction in the production activities. The Company strives to reduce the negative impact on the environment from energy use by periodically monitoring the implementation of energy efficiency in the production process, through the ISO 50001:2018 Energy Management System in accordance with the company’s integrated policy.

Energy efficiency is one of the focus of the continuous improvement in the production processes. In the last 3 years, the Company has succeeded consistently reducing the intensity of electricity consumption by 5% and steam by 3.75%. The efforts to reduce the intensity of electricity and steam were carried out by optimizing equipment/machine operate for production or non-production process and operate machine or equipment which saving energy.

EMISSION REDUCTION

Contributes to UN SDG :

The company realizes the important role and impact in fighting climate change. Therefore, the Company prioritizes actions to reduce carbon footprint and reduce waste. This is not only to meet government requirements, but also to make a positive contribution to fighting climate change.

In overall, the intensity of our energy use has decreased by 5% and the use of fossil fuels has decreased by 6% compared to 2021. Going forward, the Company will continue to improve its performance significantly. In addition, the renewable energy consumption is also increased from 2021, because the company has implemented an unbundled REC (Renewable Energy Certificate) from national grid (PLN). Furthermore, the Company start to implement solar power generator which installed on the roof of several buildings (warehouse, office, converting production, and public facilities)

SOLID WASTE MANAGEMENT

Contributes to UN SDG :

The company implement solid waste management in accordance to Agreement of Environment Appropriateness by the Governor of East Java. The activities are monitored, evaluated and reported every 6 months to referred government institute.

The Company commits to minimizing waste and maximizing opportunities to reuse waste materials through the ‘3R’ strategy—reduce, reuse and recycle which helps us to maximize the value of resources at every stage of the life cycle, as stated in the Company’s policies. Company activities in apply 3R strategy against hazardous and non-hazardous waste as following :

- The generated bottom ash waste from the coal burning process at the power plant is utilized 100% by the Company for producing of multi-blocks and road base, which has a utilization permit from the related Government.

- Non-hazardous waste from the company’s activities is utilized to create new economic value, such as: pallet wood scraps are made into new pallets, and strapping bands from the unpacking process are made into crafts in CSR activities

The company get recommendation for the activities from referred government institute. Until the moment, the company did not incur any fines or penalties for violations of environmental regulations. There were no industrial accidents or spills.

BIODIVERSITY

Contributes to UN SDG :

The Company through APP and suppliers is committed to protect and conserve Indonesia’s key animal species and their habitats. Amongst Indonesia’s diverse animal species, APP focuses on three species which are the Sumatran tiger, Sumatran elephant and Bornean orangutan, many of which use our pulpwood suppliers’ concession areas as their corridors or home range. The concession areas of our suppliers are routinely monitored to determine the distribution and population of these animals. This allows us to identify high priority areas for conservation. In addition, we implement wildlife-friendly concession management practices and wildlife corridors, conduct operations to sweep for snares, and implement programs to mitigate human-wildlife conflicts in these concession areas. The company supports operational funds for the collaboration between pulpwood suppliers with ECOSITROP in the integrated Orangutan conservation training programs include Orangutan evacuation simulations and Orangutan rapid surveys (detection and monitoring) on foot, drone and cameras traps.

|

Orang Utan Borneo |

Harimau Sumatera |

Gajah Sumatera |

The company commits to support supplier’s programs and activities to reduce human-wildlife conflicts across its supplier’s concession areas. To prevent and mitigate conflicts, the suppliers implement standardized procedures across operations in addressing conflict risks. This includes conducting rapid survey before harvesting activities to ensure minimized impact to the wildlife. Routine trainings are also provided to our workers, contractors and communities which include education and awareness on how to prevent, avoid and mitigate conflict with wildlife. (link)

OHS MANAGEMENT

The company prioritizes occupational health and safety (OHS) protection for all parties involved in our Business and committed to protecting the health and safety of our employees according to applicable laws and regulations and meet ILO standard requirements. We also require our contractors and suppliers to implement the same policies. As determined by the provisions of the Minister of Manpower and Transmigration, we have implemented Occupational Safety and Health Management System in our production facilities and have obtained SMK3 certification.

The Company develop, implement and maintain procedures to regulate safe work practices and hazards and risks within the organization. We define and regulate the task and responsibilities of K3 and ensure the provision of facilities and infrastructure needed to prevent accidents in the workplace and anticipate and mitigate potential emergency response events. We also provide personal protective equipment (PPE) and training related to K3 to prevent accidents in the workplace.

Road to Vision 2030, we have compiled and implemented a Safety Performance Index (SPI) program since 2019, as leading indicator for OHS evaluation and carried out by whole managements and its employee in OHS culture and work productivity. The SPI is routinely monitored and evaluated through internal audits and management reviews related to the implementation of SMK3 and ISO 45001:2018 Occupational Health & Safety Management System (OHSMS). This review was carried out together with the team of the OHS Steering Committee (P2K3).

|

SMK3 |

In dealing with the COVID-19 pandemic situation, the Company also makes strategic efforts to maintain the safety and health of workers in the midst of the COVID-19 pandemic with the development, implementation, and maintain the COVID-19 pandemic preparedness and response procedures based on government regulations and references from international organizations to protect workers so that operational activities continue to run effectively and safely. We provide masks to all workers, regularly disinfect all work facilities, also ensure that employees infected with COVID-19 are provided with health care facilities so that they can actively return to work.

As part of women empowerment program, the Company implements health programs for female employees that aim to improve health and work productivity including free pap smear examinations, provides lactation rooms for breastfeeding mothers, exercises for pregnant women, and develops health and educational articles.

In 2022, the Company received an award for its Covid-19 efforts and women’s health programs in the form of a Platinum Certificate from the Provincial Government of East Java and The Ministry of Man Power Republic of Indonesia for the Prevention and Management of COVID-19 Program in the Workplace; and GP2SP Certificate from the Ministry of Health of the Republic of Indonesia for the Healthy Productive Women Worker Movement Program in the Workplace.

SECURITY MANAGEMENT

The Company prioritizes protecting and maintaining security and order for all parties involved in the Tjiwi Kimia area (employees, partners, contractors, guests, etc.). We are fully committed to enforcing security regulations, facilitating and providing services to all parties in order to create security, order and comfort while in the company area.

The implementation of the security program at Tjiwi Kimia refers to the applicable security regulations, including the program to develop security awareness on an ongoing basis in creating a safe, orderly and controlled work environment, as following :

- Implementation of security management based on preventive action against potential disruptions to the company's operations.

- Avoid or minimize security risks through the implementation of security strategies that are in accordance with risk identification and reviewed periodically.

- The restricted area is protected from all threats of sabotage, attack or acts that cause damage, interruption of work, loss of life and leakage or interception of important information networks.

- Provide socialization to all employees, partners and contractors to have high integrity and honesty with the company.

- Install signs and other equipment to facilitate and support security in the company area

- Perform internal and spatial traffic management to mitigate and eliminate security risks.

- Conduct physical inspections and validate document requirements for people (employees, partners & contractors), goods and vehicles entering and leaving the company area.

- Conduct periodic patrols and monitoring of all areas of the company.

- Providing media and postal services in critical areas for complaints if there are things that have/potentially disrupted the security and stability of the company

We periodically evaluate the performance of security programs in order to develop a safe, orderly and controlled work environment in maintaining and protecting all parties and assets in the company area. The company also prioritizes security in the field of transportation and export-import activities and has been certified C-TPAT (Custom And Trade Partnership Against Terrorism) or GSV (Global Security Verification), which is a form of commitment between the government and the private sector to build cooperative relationships with the aim strengthening and enhancing the security of all international supplies. This includes the following:

- Security Procedures and Points of Origin

- Physical Access Monitoring

- Container and Trailer Security

- Employee Safety

- Physical Security

- IT Security

- Security and Threat Awareness Training

|

Global Security Verification |

AEO Indonesia |

Moreover, the Company always carries out inspection procedures, supervision from entry to exit, either supervision until the goods are sent to their destination by working with outside parties who have been supervised by other security institutions. Due to the successful implementation of a comprehensive security program, Tjiwi Kimia received the AEO (Authorized Economic Operator) certification, which is a trust given by customs regarding customs clearance, and international recognition.

SOCIAL COMPLIANCE

We acknowledge that our operations, as well as those of our suppliers, may subject us to human rights violations. To avoid any potential human rights violations, we conduct comprehensive audits and risk assessments at each of our mills, ensuring that risks are managed in accordance with the United Nations’ and International Labor Organization’s (ILO) Guiding Principles on Business and Human Rights. Our Human Rights Policy also addresses a wide range of human rights issues and situations that may arise during our operations be it in our main operations or through our suppliers.

As per regulations, the minimum age for employment in the company in any capacity is 18 years. We aim to prevent all forms of child labor and rigorously enforce these principles at our operations.

In 2022, we provided 4,987 hours of human rights training to our employees, with 100% of our employees participating, which focusing on socialization and education regarding the importance of human rights. Academy teams constantly reviews, reassesses, and re-evaluates its human rights policies in order to improve it beyond the scope of what is regulated and required.

The Company strive to provide the tools necessary to cultivate a passionate and skilled workforce. We focus heavily on training for all employees, with an emphasis on the development of technical skills, managerial abilities, and leadership qualities. Through our APP Academy including the Company, we develop and implement the Company’s various training programs. In 2022, we conducted an average of 13 hours of training per employee.

For employees approaching retirement, we have a dedicated program that equips them with the knowledge and skills necessary to earn an income once they retire. Farming techniques, entrepreneurship, husbandry, handicrafts, and home industries are all covered in training. Similarly, we offer various training initiatives such as financial planning to assist our employees in managing their income.

We recognize that investing in our employees’ training and development is critical to building and maintaining a world-class workforce. Our training and development programs have provided an excellent return on investment. Developing broad, technical skills as well as managerial and leadership abilities requires a concerted effort by the entire organization. The entire organization from site supervisors to company executives—has a uniform approach to training to ensure high levels of employee performance and engagement.

BUSINESS CODE OF CONDUCT

Contributes to UN SDG :

We are committed to upholding the highest ethical standards. This is reflected in our values of honesty, fairness, and just treatment, which apply to all our stakeholders, including our employees, customers, suppliers, business partners, and communities. Our Business Code of Conduct (BCoC) was created to provide us with a set of expectations for ethical behavior when conducting business. Tjiwi Kimia takes after APP’s group level policies, which addresses a broad category of business situations, including a Anti-Bribery & Anti-Corruption (ABAC) policy.

Our ethics and compliance program evaluated by conducting an annual survey to gather information and knowledge about employees’ awareness of the Company’s implemented ethics and compliance programs. The results were then used for the continuous development of ethics and compliance education and socialization programs, including the BCoC training that is mandatory for all employees

We expect the same level of commitment of ethics and compliance from all business partners. In this regard, the Company has been developed the Supplier Code of Conduct (“SCoC”) applicable for all business partners and communicated to them, particularly independent wood suppliers and outsourcing firms. As of the end of 2022, all wood fiber suppliers and approximately 78% of our outsourcing companies have signed the SCOC and agreed to adhere to all principles.

In 2022, the Company establish a new independent Whistleblower Channel in the Corporate website to improve accessibility for all stakeholders in raising concerns. Throughout 2022, the company received a total of 6 whistleblower reports, as following: 6 reports assigned to additional investigations (reviewed and commissioned), 1 report closed due to insufficient evidence, 2 report resulted in Management Actions. In 2022, 3 cases were resolved.

CORPORATE SOCIAL RESPONSIBILITY

Contributes to UN SDG :

The Company’s CSR Programs emphasizes community empowerment, to promote social-economy in new business opportunities, developing Small-Medium Enterprises (SME) and boost community creative-economy around the company, so the society welfare can grow. Furthermore, the CSR program also pays attention to capacity building programs for the community and company employees in order to have a sustainable positive impact on the community, employees and the Company.

Following are some of the Community Empowerment activities as part of the implementation of the Company's CSR Program including:

SME (Small & Medium Enterprises)

- Oyster Mushroom Cultivation - This program is one of the activities to create business opportunities - home businesses in company ring 1 villages. This business is run by housewives in their spare time to be more productive. To increase their selling value, they create mushroom products into a variety of delicious processed mushroom products such as mushroom chips, mushroom satay, mushroom pepes to tofu mercon which tempts the taste buds of buyers.

- Expansion of the Bento Banana Cake Market - A massive increase in sales, from only selling 10 boxes of banana cakes per day to 200 boxes per day, was achieved by MSME players with the Bento brand Banana Cake after receiving assistance from the Company's CSR. In this mentoring program, Banana Cake SMEs are guided in obtaining certificates for Home Industry Food Production, then this product is promoted at every company event, used as one of the company's menu dishes at meetings and events and as company gifts for company colleagues. The last step to break sales, the Company's CSR team redesigned product packaging to make it more attractive and have high selling value, now sales have started to climb up to 200 boxes per day.

- Market Expansion of Isokaya Brand Cassava Chips - This SME industry also have an opportunity to receive assistance in product market development from the Company's CSR. Isokaya has obtained a PIRT permit before receiving assistance so that the assistance focuses on expanding the market through packaging improvements and the inclusion of Isokaya products at the UMKM exhibition together with UMKM products assisted by the APP. The recent packaging changes and the joining of products in the MSME product exhibition were able to break down the sales of Isokaya products and as a result this processed cassava-based business was able to generate a net profit of up to IDR 8 million per month and has been able to develop markets in almost all major cities of East Java, Jabodetabek and Bali.

Company's CSR does not only stop at the top, community empowerment will continue to be improved to ensure the welfare of the community around the company is well maintained and sustainable.

Business Incubation Training Program

To support the government in the program to stimulate the economy of the SME sector, especially women, Tjiwi Kimia collaborated with the Syahrir Doctoral Foundation – Womenpreneur Community (WPC) to organize a community empowerment program in the form of Business Incubation Training. This program has been implemented twice by Tjiwi Kimia together with several companies in APP. The training aims to advance and develop the fostered MSME actors to be more independent, and focus on product development and marketing.

This program is in line with the SDGs and APP SRV 2030. Through the People pillar, APP is committed to empowering the community, including women, around APP's operational areas and its suppliers. As a result, Tjiwi Kimia has been able to support several assisted SMEs to become more independent and able to expand their market so that the amount of production increases rapidly.

PAMSIMAS Development Program for Community

PAMSIMAS is Provision of Drinking Water and Sanitation Community Based. This program owned by government that started in 2008 aims to provide access for people who do not yet have access to drinking water and proper sanitation.

Singkalan village, Balongbendo sub-district, is one of the villages receiving phase III PAMSIMAS assistance from the government in 2017 with 35 house drains, while the pump capacity can supply more than 200 house lines. Many residents hope to be able to access clean water from PAMSIMAS because in general the water in Sidoarjo Regency is of poor quality.

Responding this issue, CSR Tjiwi Kimia is supported by the APP HQ to aid with the PAMSIMAS Development Program. In its implementation, CSR Tjiwi Kimia cooperates with the NGO Habitat for Humanity Indonesia (HFHI) to expand residents' access to clean water. Some of the actions taken to realize the program are:

- Construction of water towers to increase the capacity of clean water supply.

- Installation of distribution pipes to residents' houses

- PAMSIMAS management

- Program assistance

The Singkalan Village PAMSIMAS Development Program has been successfully implemented in 2021 with the number of beneficiaries increasing from 35 house drains to 135 house drains. PAMSIMAS management is managed by BUMDES independently. With good assistance from the HABITAT Team and continuing socialization of "The Importance of Clean Water for Life", now, in 2023, PAMSIMAS users will increase to 251 household channels.

TRANSPARENCY & STAKEHOLDER ENGAGEMENT

Stakeholders are defined by the Company as any group that expresses an interest in our operations or their consequences. We monitor global trends and participate in discourses concerning critical issues affecting our business in order to identify and respond to stakeholder expectations. We promote open dialogue with all our stakeholders, as demonstrated by our annual Stakeholder Advisory Forum (SAF), during which stakeholders can express their concerns and opinions and we provide updates on our sustainability initiatives, including our GHG reduction program, ESG performance targets and progress, ESG governance.

Transparency and constructive dialogues with stakeholders are two aspects that we continuously strive to master. To do so, we have established a wide range of engagement channels, from periodical reports, websites and dashboards, grievance procedure and, chiefly, the SAF.

APP Group Sustainability

APP Group Sustainability

Growing Our Tomorrow

Our vision is to produce efficient and innovative pulp and paper through responsible forestry practices.

Learn More